Key points

• Function: A septic junction box is a crucial part of a septic system. It spreads out the wastewater from the septic tank into several drain field lines.

• Design: It’s usually made from tough materials like concrete or plastic and has multiple outlets for the drain field lines. This ensures the flow is even to each line.

• Maintenance: It’s important to regularly check and upkeeep the septic junction box. If it gets blocked, it can cause big problems, like a broken system or polluted groundwater.

Contents

- 1 Key points

- 2 Understanding the Septic Junction Box in Managing Wastewater

- 3 Definition and Functionality

- 4 Understanding Electric Parts

- 5 Maintenance and Inspection Protocols

- 5.1 Characteristics of Plastic Distribution Boxes

- 5.2 Durability and Longevity

- 5.3 Advantages Over Other Materials

- 5.4 Installation and Positioning

- 5.5 Integration with the Septic System

- 5.6 Guidelines for Proper Placement

- 5.7 Function in Effluent Dispersion

- 5.8 Role in Equal Distribution to Drain Field

- 5.9 Impact on Drain Field Efficacy

- 5.10 Maintenance and Troubleshooting

- 5.11 Common Issues and Solutions

- 5.12 Periodic Assessment for Optimal Performance

- 5.13 The Link Between Tank and Drainage Area

- 5.14 Regulating the Flow from Tank to Field

- 5.15 Ensuring Balance in the System

- 5.16 Choosing Materials and Design

- 5.17 What to Think About When Choosing a Box

- 5.18 Design Features for Better Operation

- 6 Frequently Asked Questions (FAQ)

Understanding the Septic Junction Box in Managing Wastewater

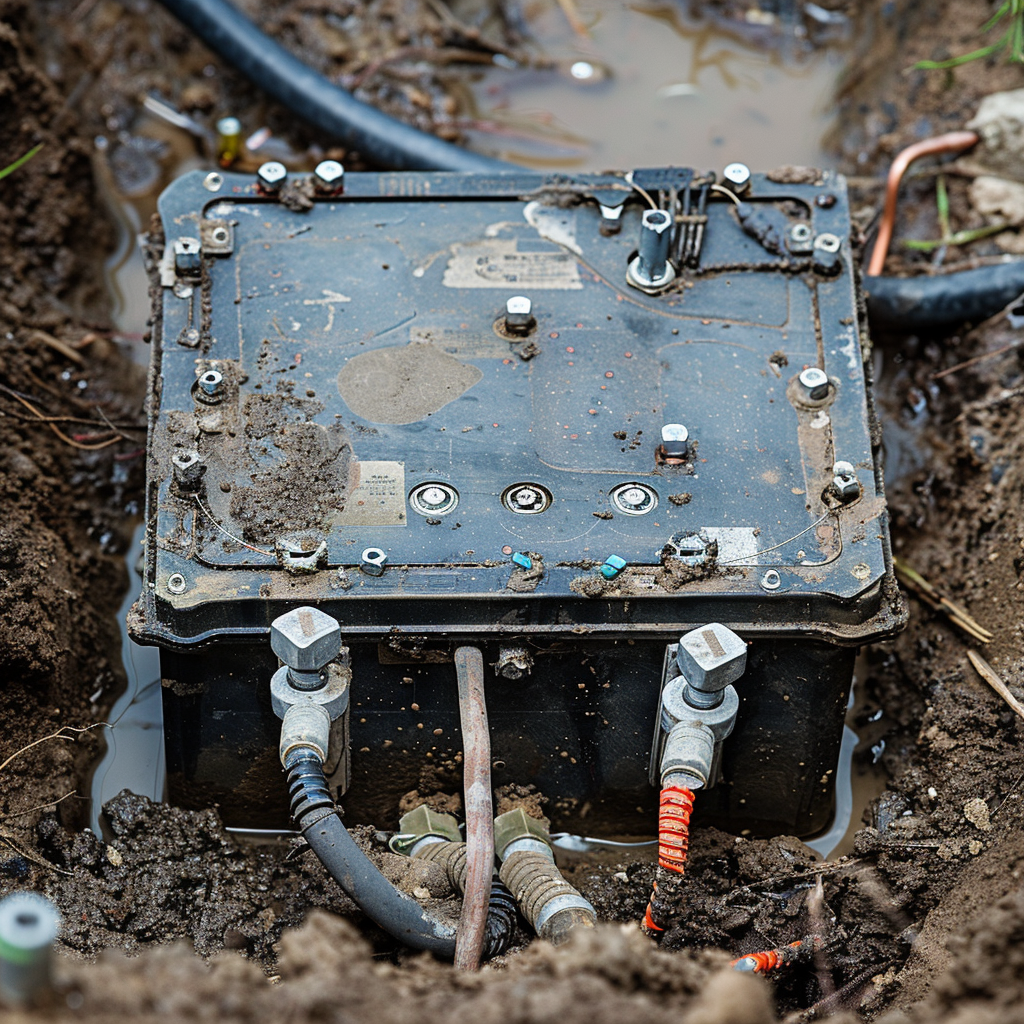

The septic junction box might not be as famous as septic tanks or drainfields, but it plays a vital role. It might go unnoticed, but it’s essential; it acts as a passage that evenly sends waste water from the septic tank to different parts of the drainfield. The box is usually made of tough plastic or concrete and has multiple openings for pipes that go to various sections of the leachfield. It has internal walls or dividers that control the flow, making sure no part gets too much waste. This balance helps treat the waste water better in the soil and makes the septic system last longer.

If you don’t take care of this important box, it can cause big problems for the system. A tight seal between the junction box and its pipes is key to prevent leaks and clogs. It’s important to keep an eye on the box for checking and fixing things to keep it working well.

When there are issues with the septic junction box, nasty waste water could end up on top of your lawn or cause backups—both things you definitely don’t want because they’re risky for your health and can mess up your property. By knowing how crucial this box is, homeowners can take care of their septic systems better. This way, they help protect the environment and keep their waste water treatment effective.

Definition and Functionality

The Septic Tank Electrical Junction Box is basically the control center for a house’s septic system electrical connections. It’s where wires from the septic pump, alarms and different sensors come together. This makes it easier to send power and messages between the parts.

Understanding Electric Parts

A junction box is made up of important parts such as circuit breakers, GFCIs (ground fault circuit interrupters), relays, and terminal blocks. These parts work together to make sure electricity gets delivered safely throughout a septic system without causing overloads or short circuits.

Importance in Septic System Function

The junction box is crucial for keeping a septic system running. It not only powers the system but also keeps the septic pump and alarm systems working together right. This stops breakdowns from happening.

Link to Septic System Security

For septic safety, the junction box is very important. It safeguards the complex equipment and the homeowner from electric accidents that might happen because of water or some unexpected issues in what are often wet places.

Electric Safety Steps

Safety measures we’ve put in place include setting up strong, weather-resistant cases and using GFCIs. They quickly cut off electricity if there’s a problem, reducing the danger of electric shocks or fires.

Maintenance and Inspection Protocols

It’s wise to regularly check your junction box to make sure everything’s working smoothly. Maintenance should include looking for rust, making sure wires are tight, and testing GFCIs. It’s also a smart move to hire a pro now and then for a thorough inspection to make sure everything meets local codes and works like a charm.

If you’re exploring how septic systems work, get to know the parts and what they do. The plastic septic distribution box is super important in these systems because it’s where all the action happens.

Characteristics of Plastic Distribution Boxes

These boxes are made from tough plastics that help spread out wastewater—or effluent—into the leach field. They have to be sturdy to handle the pressures underground and all kinds of weather.

Durability and Longevity

Choosing plastic for your distribution box is smart since it’s strong. These boxes put up a good fight against damage, stay dry, and can take on whatever soil throws at them without needing much fixing or replacing.

Advantages Over Other Materials

What’s more, plastic boxes are better than say concrete because they don’t weigh a ton, which means they’re a breeze to move around and set up. They aren’t likely to crack or rust either, something concrete ones tend to do.

Installation and Positioning

Getting the placement right when setting up your plastic distribution box is key. It has to be just right so the effluent goes evenly to the pipes in the drain field.

Integration with the Septic System

The box links up with both the septic tank and the leach lines. It sorts out the wastewater coming from the tank and splits it up evenly over the leach field, so you don’t have any trouble with overload and your drainage area lasts longer.

Guidelines for Proper Placement

To work its magic, the box has to be on flat ground; otherwise, things could get messy with an imbalanced flow. It should sit deep enough so it won’t freeze or break but still be easy to reach when you need to fix something. If it isn’t set up just so, you could have problems with how the wastewater spreads, which might mess up your system.

A distribution box is central to getting wastewater from your tank out into your drain field in a balanced way, making sure your whole setup keeps running efficiently.

Function in Effluent Dispersion

The D-box is where the final cleaning happens after the septic tank does its thing by separating solids from liquids. It then sends the effluent down different paths in the drain field, making sure each part gets an even share to do its job well.

Role in Equal Distribution to Drain Field

Spreading it out right is critical, cause if you don’t, some spots might flood and that can ruin things fast. The D-box has special outlets all at the same level so the flow stays steady to every corner of the field.

Impact on Drain Field Efficacy

The success of your drain field really hinges on how well the D-box works. If it’s not up to scratch, you could end up with soggy patches that back things up. When effluent flows even-Steven, it means every part of the field is used properly, keeping it in tip-top shape.

Maintenance and Troubleshooting

You gotta keep an eye on that D-box, checking for clogs, even holes, and signs of wear-and-tear. Sorting out issues often means getting rid of junk in pipes and fixing any tilts that throw things off balance.

Common Issues and Solutions

As time rolls on, you might find sludge or roots causing headaches in your D-box. Ground shifting could also knock the box out of whack. Just keep it clean, patch up any damage, and swap out parts when needed.

Periodic Assessment for Optimal Performance

Last of all, don’t skip on regular checkups. Catching small troubles early means avoiding big fixes down the road. Keep notes on what’s changing; they’ll give you a heads-up if something’s about to go wrong.

The Link Between Tank and Drainage Area

The connection between the septic tank and the drain field is a critical part of the setup. The wastewater first gets partial treatment in the septic tank, then moves to the distribution box, which sends it off into different leach field lines. This linkage is key to keeping the whole system running smoothly.

Regulating the Flow from Tank to Field

Distribution boxes control the flow of treated water from the septic tank to the drain field. They’re designed to divide the liquid equally so that each section of the field gets the right amount. By doing this, we avoid putting too much strain on any single part, which might cause the system to fail too soon.

Ensuring Balance in the System

It’s important for the whole drain field to be balanced for the sewage system to work right, and the distribution box is key to this balance. By spreading out the fluid consistently, it stops any one area from getting too much and allows for proper filtration through the soil.

Choosing Materials and Design

Picking the right materials and design for a distribution box is super important. They’re usually made from concrete, plastic, or occasionally fiberglass. The material has gotta be tough to handle being underground and last a long time without corroding. The design needs to take into account things like weather and soil conditions around it.

What to Think About When Choosing a Box

Picking the right distribution box is crucial. You need to think about how big your system is, how much waste water you’ll have, and what special things you need for your site. The size of the box should match up with these factors so it works well and lasts a long time.

Design Features for Better Operation

To work even better, many distribution boxes have special design features such as:

- Baffles or Tees: These help send the flow equally into all the output pipes.

- Tilt Adjustments: Some boxes can adjust their slope to handle the flow more effectively.

- Seals and Risers: Good seals stop leaks and risers make it easier to get into the box for fix-ups.

All in all, septic junction boxes hold an important role in managing waste. Their proper setup, regular maintenance and careful management are essential in avoiding problems and making sure a septic system lasts as long as it should.

Frequently Asked Questions (FAQ)

What is the primary function of a septic junction box?

The primary function of a septic junction box, often referred to as a D-box or distribution box, is to receive septic tank effluent and ensure its uniform distribution to the field lines of the disposal system. This element is critical in maintaining system balance and ensuring equal flow to all parts of the leach field.

Can a homeowner install a septic junction box themselves?

While a savvy homeowner with the right tools and knowledge may attempt to install a septic junction box, it’s generally recommended that this job be performed by a licensed general contractor or plumber. Proper placement, slope, and depth are vital for system efficiency and to meet local building codes. Additionally, working with components such as power lines and ensuring the wastewater network operates safely are tasks usually best left to professionals.

What materials are most common for constructing septic junction boxes?

Septic junction boxes are commonly made from durable materials like concrete or heavy-duty plastics. These materials are selected for their longevity and ability to resist the corrosive nature of sewage water. The choice between concrete and plastic often depends on local soil conditions, maintenance considerations, and the specific design requirements of the septic system in question.

How does the depth of a septic junction box affect its performance?

The depth at which a distribution box is placed impacts its performance significantly. It requires careful consideration to match frost depth and soil cover requirements, ensuring the wastewater flows correctly through gravity and evades issues with freezing. Distribution boxes should be set at a depth specified within drainfield trench depth specifications to guarantee optimal functioning.

Are adjustments ever needed for a septic junction box?

Yes, adjustments to a septic junction box may be necessary over time due to soil settlement or changes in distribution patterns. Inspections can reveal if these changes have impacted how effluent flows into the leach fields. If there’s a problem, corrective measures may involve alterations to the box’s level, adjustments of its outlets, or clearing blockages in the system.

What signs indicate an issue with the septic junction box?

Several warning signs may indicate leach field issues originating from the septic junction box including soggy ground above the drain field, strong odors, backups inside the home, or noticeable sewage spills on the property. If any of these signs are observed, it may suggest failures within the distribution box such as line blockages, incorrect slope or positioning, and would require immediate inspection and possibly repairs.

How often should inspections be conducted on septic junction boxes?

Regular inspections of septic junction boxes are essential for maintaining them in good working condition. The frequency can vary based on many factors but generally aligns with routine septic system maintenance – every 1 to 3 years is typical. During inspections, plumbing experts assess all parts, ensuring they’re functional and without significant wear or damage.

Can weather conditions affect a septic junction box's functionality?

Absolutely, weather conditions such as heavy rainfall can challenge the absorptive capacity of leach fields and lead to over-saturation. In contrast, extreme cold can lead to freezing if the box isn’t buried below the frost line. Adequate soil cover and proper depth installation are necessary precautions against weather-related problems for efficient effluent treatment.

What role do design criteria play in selecting a septic junction box?

Design criteria dictate many aspects when selecting a septic junction box; these include size, shape, material choice, bottom width, number of field line holes, and resistivity to effluent’s corrosive properties. Authorities set these specifications based on soil restrictions, effluent volume, and geographic location to ensure appropriate waste dispersion in varied building contexts.

In terms of maintenance, what should homeowners watch out for with their septic junction boxes?

Homeowners need to keep an eye out for any signs that could point to leaching system troubles, such as visible leach line backups or unusual moisture near drainfields. Regular checks for blockages in pipes leading from tanks to distribution boxes can prevent severe backups. The occurrence of circuits tripping related to power lines servicing pumps or alarms should also prompt an inspection, as these could signify deeper issues within the system.

I’m Tim Robberts, a seasoned wastewater treatment & septic system expert with over 40 years of experience in the field. My career began as a septic tank installer, and I quickly gained a reputation for my attention to detail and commitment to excellence. Over the years, I’ve honed my skills in designing, installing, and maintaining septic systems for residential and commercial properties.